The U.S. Department of Energy along with the State of Ohio's Coal Development Office and a consortium made up of Babcock & Wilcox, General Electric and Alstom Power will cost share in a $75 Million effort under a prime contract to the Energy Industries of Ohio, who, along with the Electric Power Research Institute (EPRI) will manage the project. The project is for full scale component testing needed prior to commercialization.

Since 2001 a U.S. public/private Advanced Ultrasupercritical (AUSC) Materials consortium has been led by EIO to find means to operate fossil fueled power plants at higher temperatures to reduce emissions. The AUSC technology is now ready to be demonstrated under this full scale Component Test (ComTest) planned for Ohio. The project team under EIO's leadership has been able to locate a suitable site at the former Ohio Edison plant which is now the Youngstown Thermal District heating plant. Additional infrastructure will be constructed to accommodate the test and EIO plans to install the first AUSC turbine on site. "This is very positive news not only for moving the technology forward but for sub-tier opportunities for Ohio's manufacturing industries as well" according to Bob Purgert, EIO President. He continued "The need for castings from Ohio's foundries, forgings and fabrication of products along with job training for skills needed to weld and install the equipment will directly benefit Ohio workers. The timeliness of the test could not be more critical in view of the proposed Clean Power Plan."

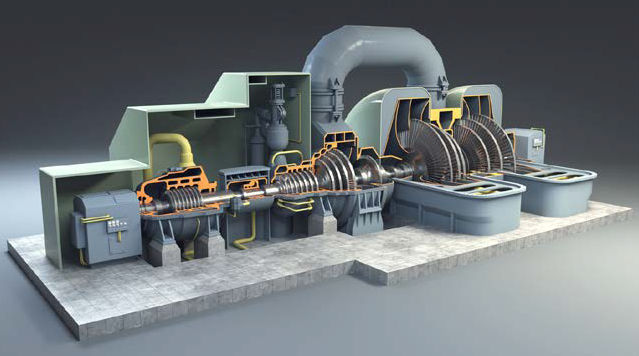

In addition to the prototype AUSC steam turbine, Energy Industries of Ohio will also test components that deliver steam to the turbine including a superheater, boiler tube membrane wall, desuperheater, steam headers, and main steam piping.